What Is a Cobot? How Collaborative Robots Reduce Production Costs

A cobot is a collaborative robot designed to work safely alongside human operators, helping companies reduce production costs while improving efficiency and consistency. Unlike traditional industrial robots, cobots are flexible, easy to program, and ideal for handling repetitive or hazardous tasks without replacing human workers. In this article, we’ll explore what cobots are, how they work, and the ways they can help manufacturers save time and money.

How Cobots Work

Collaborative robots, or cobots, are robots that work safely with people in factories. They help companies save money and work more efficiently. Cobots can work all day without getting tired, do repetitive or boring jobs, and make products quickly and accurately. They are easy to program, so workers don’t need special training to use them. Cobots also help improve product quality because they do tasks the same way every time, reducing mistakes and waste.

They keep workers safe by handling dangerous tasks like lifting heavy items or working with hot or sharp materials. Cobots can be easily reprogrammed for new jobs and fit well into existing production lines. Overall, cobots make manufacturing faster, safer, cheaper, and more flexible, while allowing people and robots to work together effectively.

Ways Cobots Reduce Production Costs

Collaborative robots, or cobots, are changing the way products are made. They help manufacturers save money and improve productivity by increasing efficiency, reducing labor costs, improving quality, enhancing safety, and offering flexibility. Here’s how they do it:

Increased Efficiency and Productivity

Cobots make work faster and more efficient in many ways. They can run day and night without tiring, keeping production going with minimal downtime. By taking over repetitive tasks, they let workers focus on more important and creative work. Their speed and accuracy also help complete jobs faster, increasing overall productivity.

See also: Guide to Choosing the Sun Life Insurance Plan That Fits

Lower Labor and Training Costs

Cobots help businesses save money on workers and training. They’re easy to set up and require no coding skills. Cobots can do several parts of a job by themselves, so fewer people are needed to finish the work. Often, one trained worker can watch over several cobots at the same time, making work faster and cheaper.

Improved Product Quality and Consistency

Cobots help make sure products are high-quality and consistent. They do tasks the same way, which keeps the work accurate and precise. By reducing human mistakes, cobots help lower the number of defective products and cut down on wasted materials. Even when producing large quantities, they maintain steady performance and uniform results.

Enhanced Safety and Lower Injury Costs

Cobots help create a safer workplace by handling dangerous tasks, such as working with heat, chemicals, or sharp tools. This keeps human workers out of harm’s way. By reducing the risk of accidents and injuries, cobots also help companies save money on insurance and medical costs.

Greater Flexibility and Scalability

Cobots are easy to reprogram, so they can quickly adjust to new products or changes in production. They work well for both small batches and large-scale manufacturing, making them a cost-effective choice for businesses of any size. Cobots can also be added to existing production lines with little disruption, allowing companies to upgrade smoothly and efficiently.

Cobots offer an efficient, safe, and flexible way to improve manufacturing. By combining precision, adaptability, and human-friendly design, they help businesses cut costs, boost quality, and stay competitive in a fast-changing market.

Industries Benefiting from Cobots

Cobots are changing the way industries work by improving efficiency, safety, and flexibility. Here’s how they make a big impact in different sectors:

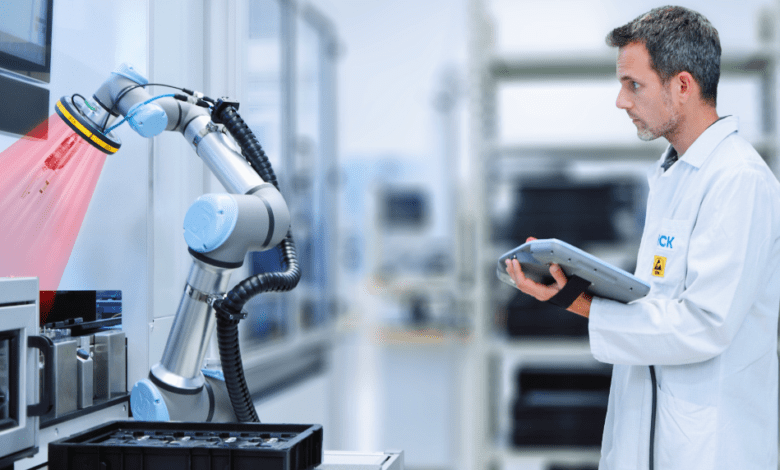

Machine Tending and Assembly

Cobots help in factories by loading and unloading materials into machines such as CNC machines, presses, and injection molders. This makes work faster and keeps workers safe from dangerous areas. They are also used in assembly work, where their precise movements help build products like electronic parts, car components, and medical devices with high accuracy and consistent quality.

Automotive and Electronics Assembly

Cobots are widely used in assembling cars and electronic products. They handle tasks like part handling, screw driving, and quality inspection with precision. Since they can safely work beside humans without barriers, they make production faster and safer. For example, Fiat uses cobots to assemble the Fiat 500 electric car, improving both efficiency and flexibility.

Metal Fabrication and Welding

In metalworking and welding, cobots assist with TIG and MIG welding, machine tending, and material handling. They boost productivity by taking over repetitive or dangerous tasks, allowing skilled workers to focus on complex jobs. Cobots also maintain consistent weld quality and can work in tough environments, such as high heat or hazardous conditions.

Packaging, Logistics, and Food Processing

Cobots can automate tasks like sorting, palletizing, and packaging in warehouses and logistics centers, making busy production lines more efficient. Their compact size and easy setup make them a great fit for these environments. In the food industry, cobots handle jobs such as cutting and packaging while following strict hygiene standards, helping to speed up production.

Cobots are transforming industries by automating repetitive work, improving safety, and offering scalable, cost-effective solutions. Their ability to work safely with humans makes them valuable tools for both large manufacturers and smaller businesses.

How to Get Started with Cobots

Getting started with collaborative robots (cobots) is easier than many businesses think. You don’t have to rebuild your whole factory, just have a solid plan and the right support to guide you. Here’s how to begin:

Identify the Right Tasks

Start by looking for tasks in your operations that are:

- Repetitive: such as packing, labeling, or loading materials.

- Dangerous: jobs that involve heavy lifting, heat, or sharp tools.

- Precision-Based: tasks that require steady, accurate movements, like assembly or inspection.

These are the areas where cobots can make the biggest difference.

Evaluate Your Needs

Every business is different, so it’s important to consider what you need from a cobot. Think about the tasks it will perform, the size and safety of your workspace, and whether you want partial automation to assist workers or full automation. Understanding these factors helps you choose the right cobot and setup for your operations.

Partner with a Trusted Cobot Provider

Working with an experienced cobot solutions provider, such as Techman Robot, can make adoption easier and more effective. They can assess your business needs and workflow, help you choose the most suitable cobot and accessories, and plan a smooth integration into your existing system. They also ensure that safety and quality standards are met, provide demonstrations, and assist in calculating your return on investment (ROI).

Train Your Team

Proper training is essential for successful cobot use. Employees should learn how to operate, program, and maintain cobots safely. Emphasize safety procedures between humans and robots, and encourage staff to provide feedback to improve performance. Most cobots are user-friendly, so even non-technical workers can learn quickly.

Adopting cobots is a simple, safe, and affordable way to modernize your business. Identify key tasks and work with a trusted provider to maximize automation, improving productivity, safety, and growth.